Tag: Prediction

6 Ways iBwave Focuses on Prediction Accuracy

July 21, 2020

Without a way to generate an accurate prediction of a network design, it can’t be trusted to perform as it’s required to – and when that happens, a lot of time and money is at risk. This is why prediction accuracy has been a focus of iBwave’s since it first started over 16 years ago. […]

chat_bubble1 Comment

visibility3081 Views

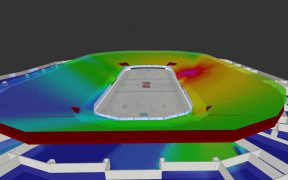

What’s the Impact of Reflection and Diffraction on Prediction Accuracy?

August 27, 2019

Depending on the venue you’re designing, considering reflection and diffraction can make anywhere from a small to a very large difference. Take a small open office space for example – reflection and diffraction probably don’t make such a large difference. But when you look at more complex venues such as a warehouse, or large manufacturing […]

chat_bubble1 Comment

visibility3395 Views