How Poor Modeling Can Impact RF Performance and Cost

Share

Intro

In May 2017 we went on a whirl wind of a User Group tour that took us to three different cities across the United States: New York, Dallas, and Newport Beach. In each user group we always like to hear from our users – what they are up to, the challenges they see out there in the field, and of course to share any stories and insights they have from all of that.

One such presentation done at the Newport Beach user group was done by Shane Rubin, Vice President – National Wireless services at Communication Technology Services (CTS). CTS has been a long-time customer of iBwave’s; in fact, they were one of our first customers about 14 years ago (thanks for sticking with us!). With the presence throughout the United States, CTS provides turnkey mobility design and deployment solutions across the entire wireless gamut: Indoor DAS, Outdoor DAS, Small Cells, Public Safety, and WiFi. They have a lot of experience, and thankfully for us, a lot of insights to share with us and the rest of the wireless community.

Shane’s presentation was entitled ‘iBwave Accuracy: The Impact on RF Performance and Cost’. And this was such a compelling presentation because it really showed how what can be perceived as small modeling errors done at the beginning of a project can lead to very large costs at the end of the project – both in terms of RF performance, and in terms of revenue and troubleshooting costs.

In Shane’s presentation he really hit the nail on the head when he started out by saying “accuracy starts with the proper foundation”, a sentiment I have heard many different times in talking to those in the industry and a sentiment we integrate into the best practices we teach around in-building wireless design in our iBwave certification program.

Without a good model to base your wireless network design on, the performance and cost of your project become significantly more at risk. That can come in the form of additional technical trips that need to be done to the site, the increased costs during implementation, delays in the project timeline, and of course the cost that comes when users of the network are not getting the experience they expect.

It’s for this reason so many of our customers take advantage of the advanced 3D Modeling capabilities in our iBwave Wi-Fi and Cellular network design software and take their time during the initial phase of the project to get the modeling absolutely right. To give you an idea of the level our customers are going with their modeling in order to ensure design accuracy, here are a few really impressive models from the CTS design team that Shane shared during his user group presentation.

So what are some modeling issues that can lead to poor RF performance and increased costs?

In Shane’s presentation he highlighted the following:

- Scale

- Body Loss and Fade

- Power Sharing

- Wall Types

And while each of these design factors can impact the performance of a network, in this post I’m going to focus on the two factors we hear most about in the field: scale and wall types.

Scale

One of the first things you do on any project is set the scale of the floor plan. Easy enough right? The problem is, even being off by just a little bit when setting the scale can cause large design issues and expenses later on in the project.

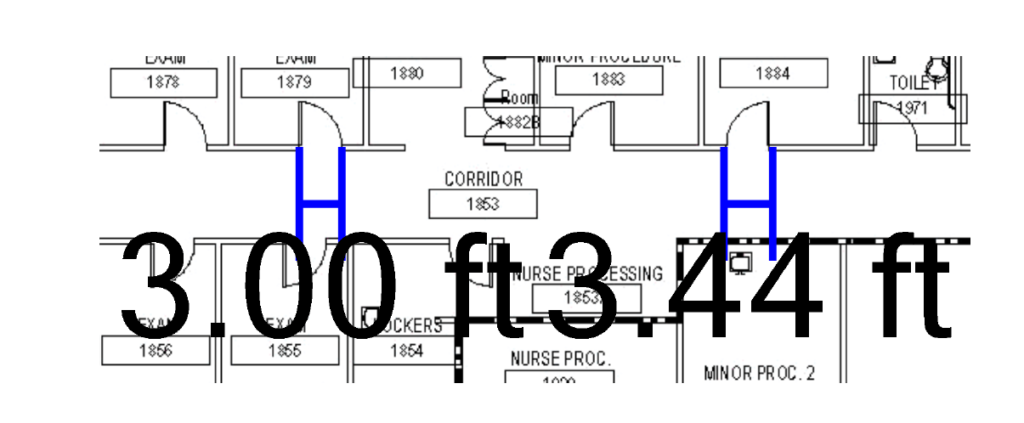

As you can see in the following image, Shane used the example of setting the scale of a door incorrectly by at 0.44 FT: 3.00 FT (incorrect) vs. 3.44 (correct).

The result of this? At an overall scale level, the difference became 160,500 SF space (correct) vs. 122,000 SF space.

What was the impact of this difference?

To get a better idea of the impact, let’s first take a look at the design of the network Shane and his team completed under both conditions: 160,000 SF scale and 122,000 SF scale.

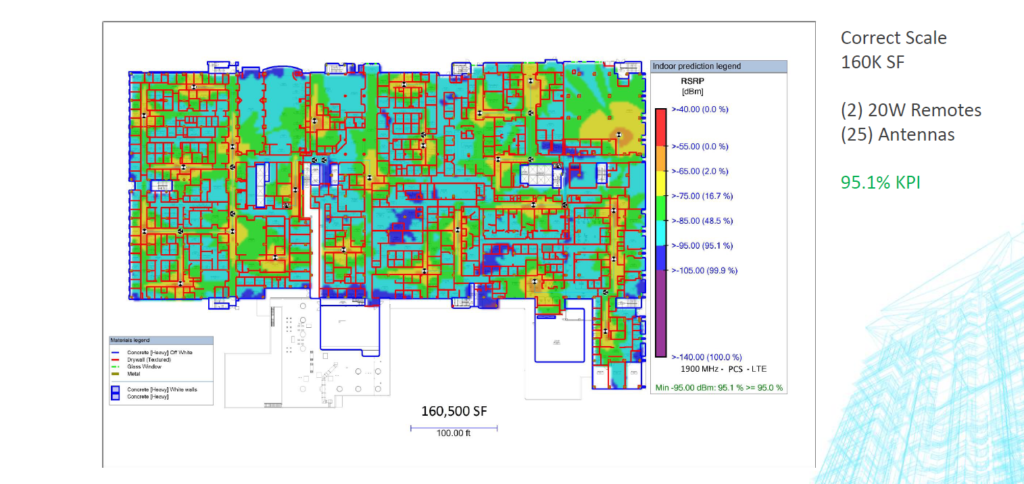

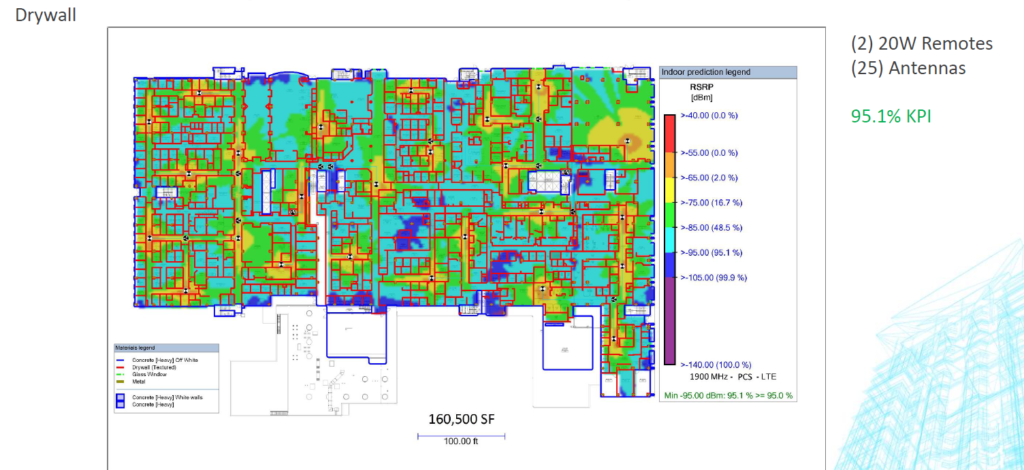

A) CORRECT SCALE: 160,600 SF DESIGN

Looking at this heat map, you can see that with the scale correctly set at 160,500 SF the design requires 2 X 20W remotes and 25 Antennas in order to achieve the 95.1% KPI

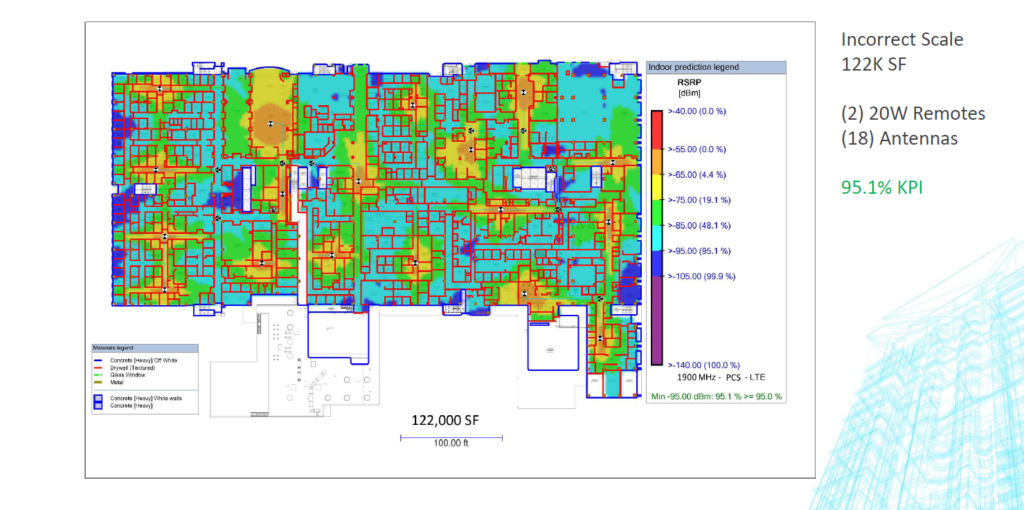

B) INCORRECT SCALE: 122,000 SF DESIGN

Looking at this heat map, you can see that with the scale incorrectly set at 122,000 SF the design requires 2 X 20W remotes and only 18 Antennas in order to achieve the 95.1% KPI

Why does this matter? Because while you are likely to please the customer with a lower design cost (18 antennas vs. 25), once the network is actually implemented in the 160,500 SF space, it will not perform as predicted – in other words, you will not really meet the required KPI, which will result in a not-so-happy customer anymore, and significant troubleshooting and re-design costs.

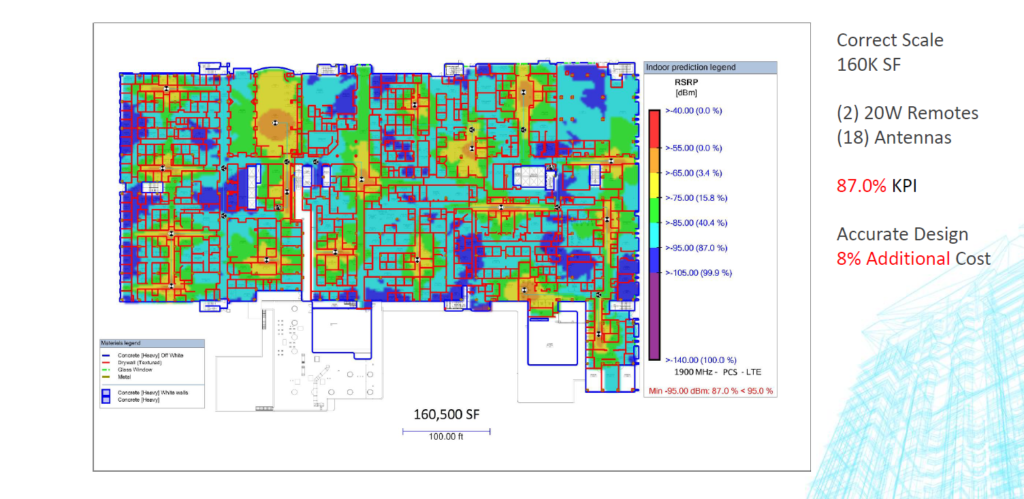

To make this point even clearer, Shane and the CTS team showed how the network design done with the scale of 122,000 SF would perform in reality with the 160,500 SF of space:

As you can see, when the network that was designed incorrectly for the 122,000 SF space is implemented in the real space of 160,000 SF with only 18 antennas, the performance fails to meet the KPI – and results in an 8% in additional costs. Interesting to see how being off by just 0.44FT when setting the scale can lead to such large performance and cost impacts later on in the project cycle.

Wall Types

If you currently use iBwave Design or iBwave Wi-Fi or have had a chance to try out a free trial, then you know that we have a very large database of materials available to use when designing. To be specific, we currently have over 70 default wall types in iBwave Design and iBwave Wi-Fi (plus you can always add your own custom wall types yourself by editing the database). And the reason is, we know the value of using the right wall materials when designing – and the impact that can happen when the right materials are not used. But what happens when the right wall type is not selected?

This was also a key topic that Shane from CTS talked about in his presentation at the user group – just how critical it can be to model using the right wall material.

To expand on this further, I’m going to use the example Shane used in his presentation.

In this example, we’ll take a look at two similar wall types – Dry Wall vs. Sheet Rock – Light – and the impact that wall materials can have on the network performance and project costs.

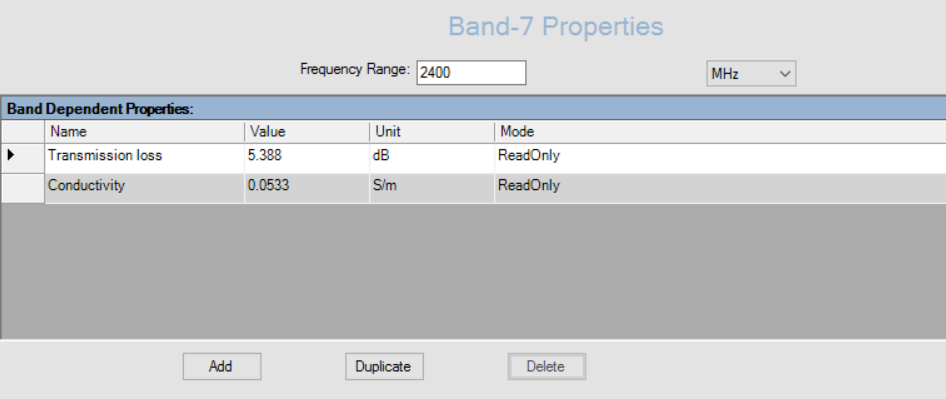

Example signal loss config for Drywall (2.4 GHz band)

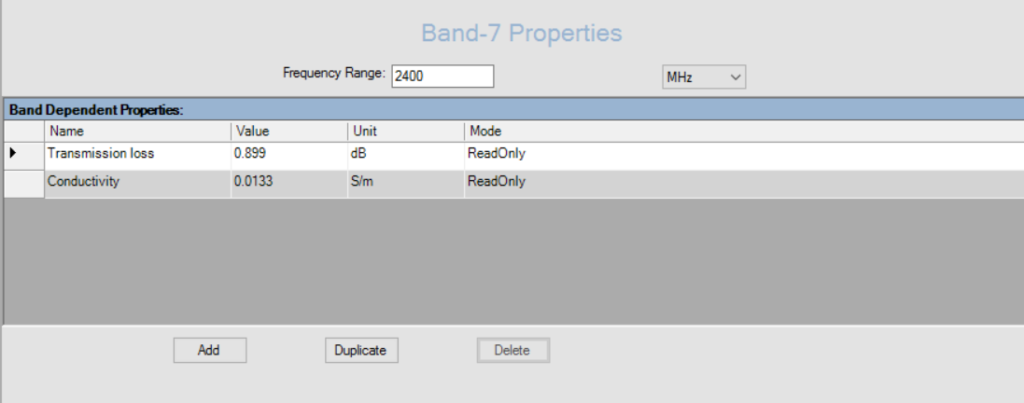

Example signal loss config for Sheetrock-Light (2.4GHz band)

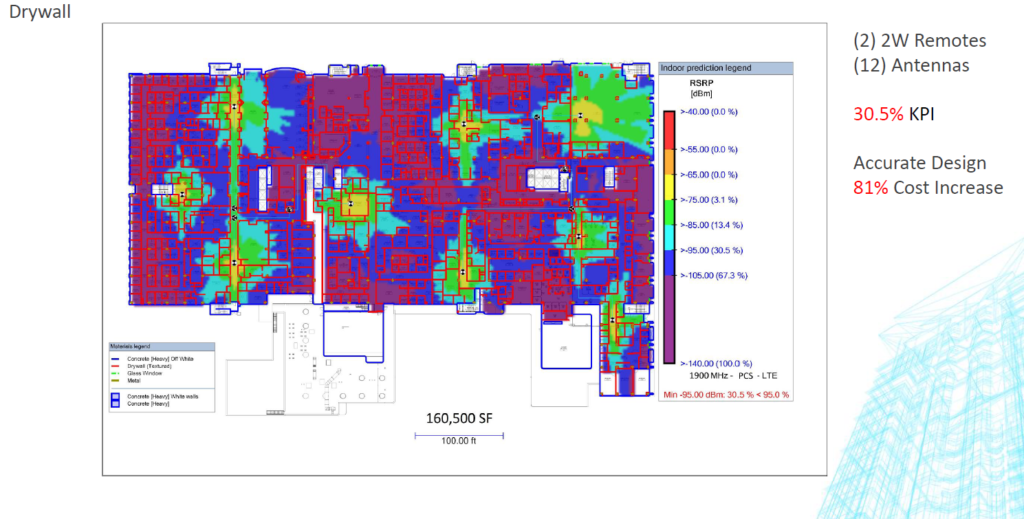

WALL TYPE: DRYWALL

Looking at this heat map, you can see that when Drywall was correctly set as the wall type, the design requires 2 X 20W remotes and 25 Antennas in order to achieve the 95.1% KPI.

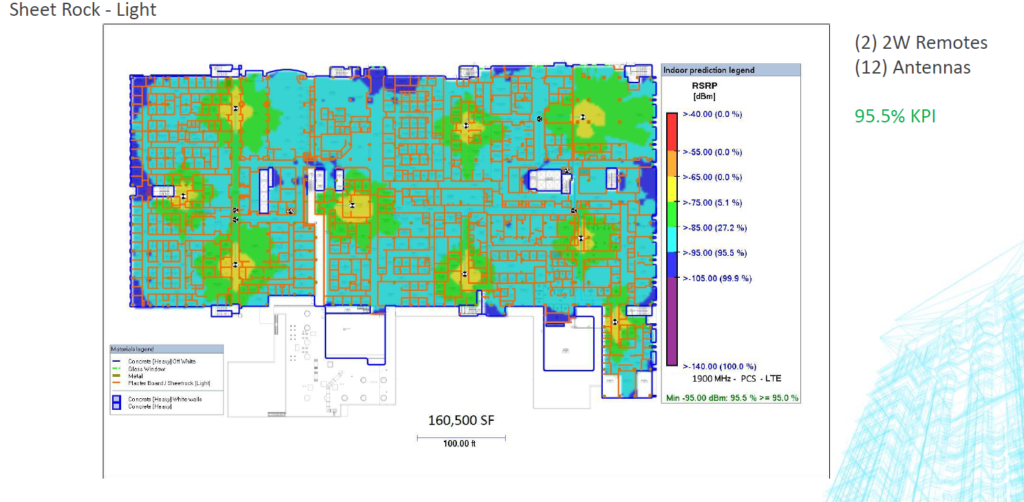

Looking at this heat map, you can see that when Sheet Rock-Light was set as the wall type, the design requires only 12 Antennas achieves a 95.5% KPI

So again, in this case – clearly the customer would be more inclined to go with the design that only requires the antennas. But, if that is not really the actual wall type – the network will not perform as predicted, and additional equipment, time and troubleshooting costs will be accumulated post-implementation.

To give you an idea of how the ‘Sheetrock – Light’ design would perform in reality with Drywall – take a look at this heat map:

As you can see, with the incorrect material, and the incorrect signal loss assigned to those materials, then the actual performance of the network is significantly at risk – in this case the KPI is reduced to just 30.5%, and the potential costs of the project can significantly increase from what was originally told to the customer – in this example, it would have been 81%

In Conclusion

Interesting to see how little inaccuracies in the design phase of a project can have such large impacts later on in the project. It is the very reason that CTS is so accurate and meticulous when they undertake the modeling phase of the design – and the reason they have so much success with their customers.

Thank you to Shane and all of CTS for presenting at our user group and sharing your valuable insights from the field with us!

What is your experience with modeling mistakes and their impact on performance and costs? Comment below to let us know.

Wirelessly yours,

Kelly

Interested in being featured on our blog? Send me an email at kelly.burroughs@ibwave.com

- Cleared for Takeoff: Private Networks in Aviation - January 21, 2025

- A Tour of iBwave Viewer - November 23, 2020

- Introducing Augmented Reality in iBwave Wi-Fi Mobile - September 10, 2020